Our Business Units

Choosing a qualified integrated services structure is more than selecting a supplier; it’s partnering with a reliable ally that will keep you ahead of the competition. Pioneers in offering integrated solutions, we guarantee a variety of options adapted to the particular needs of each client, whether they are looking for a turnkey solution or a specific service. All in one place: the VANGEST industrial complex.

New Product Design, Prototyping & Small Series

In this business unit, concepts are transformed into functional products through a comprehensive product design and development process, which integrates knowledge and technologies such as: 3D CAD engineering, prototyping using various 3D printing methods and silicone moulds, as well as rapid manufacturing and the production of small series. By working closely with our clients, we ensure their active involvement at every stage, guaranteeing faster results that strictly align with the project’s objectives.

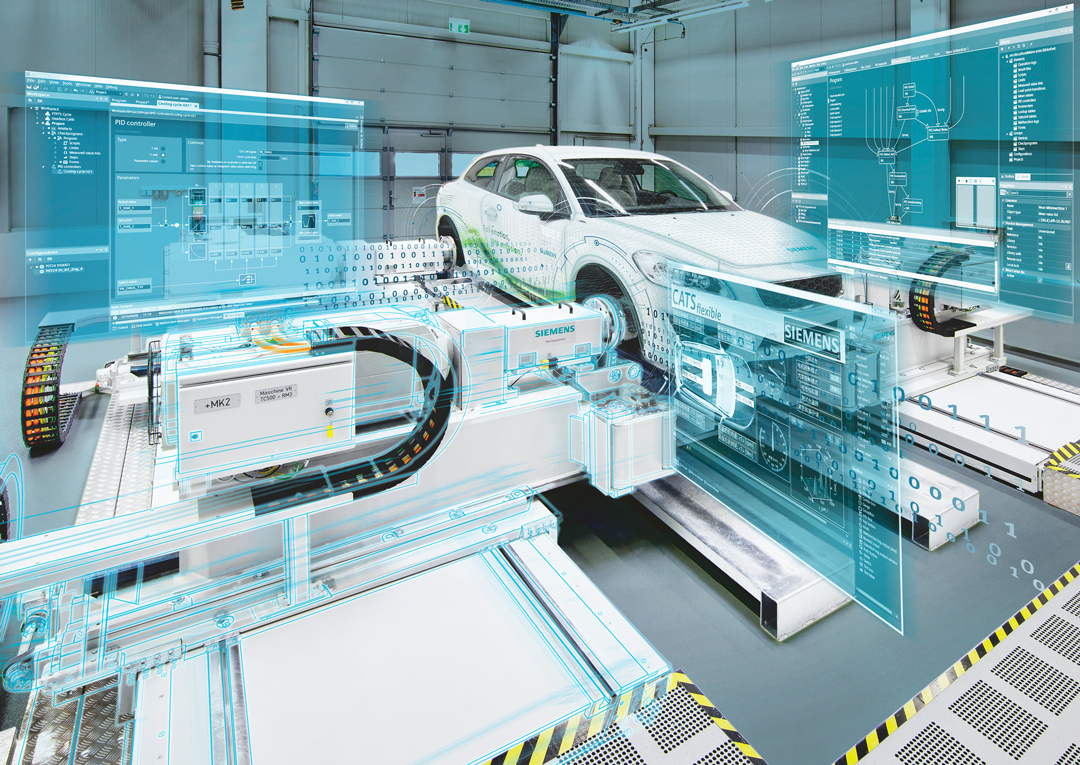

Software & Engineering Services

Since the beginning, we have pursued a relationship with CAD 3D software suppliers, not only for distribution but to transfer the VANGEST know-how to multiple partnerships, enabling our IT business units to provide Integrated Engineering Solutions: 3D engineering software (design, production and analysis) for all areas of metal machining and PLM (Product Lifecycle Management) solutions for various types of industries.

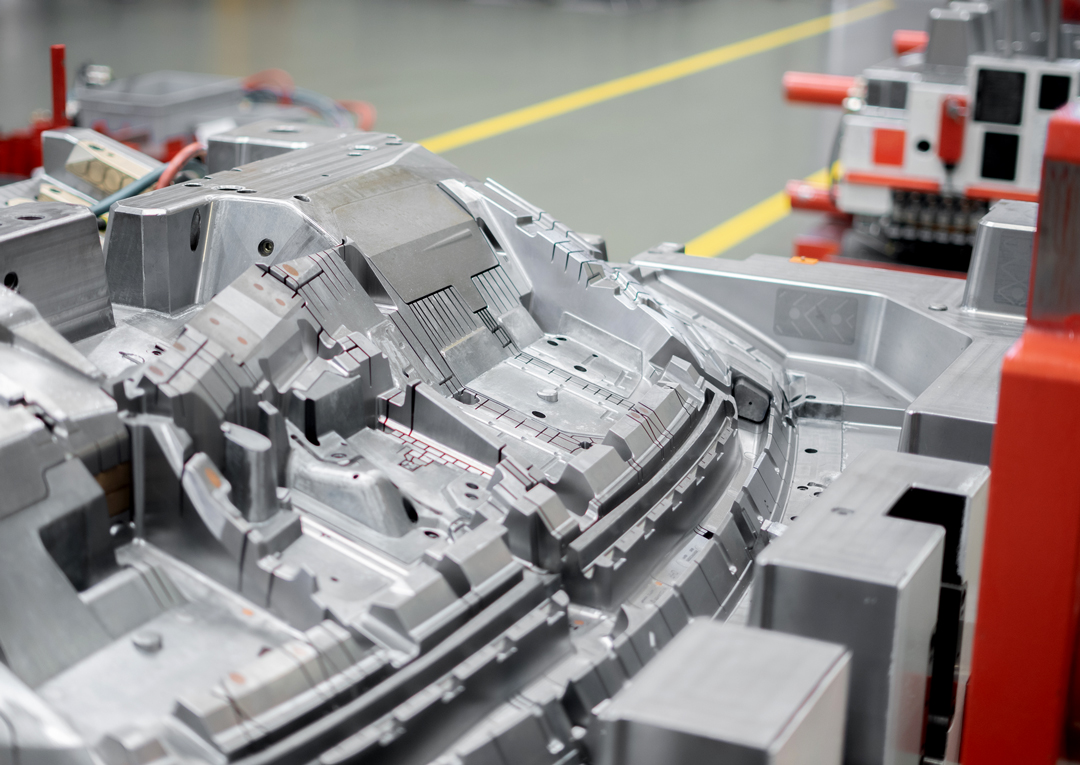

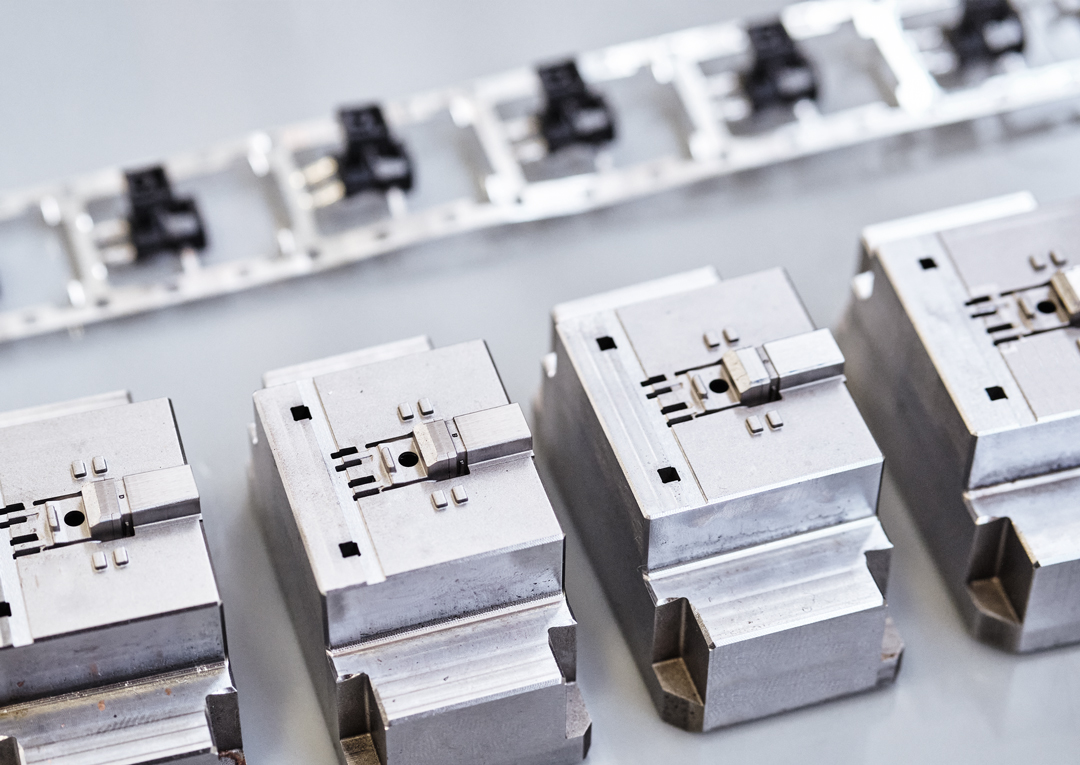

Moulds Making & Validation

In this area, our solutions include mould design, engineering and production. With dedicated resources, the mould making facilities are segmented according to their specialization: from small, high-precision moulds to large moulds (up to 35 tons). With in-house Trial and Validation Centre, we are able to ensure maximum quality and reduce delivery times.

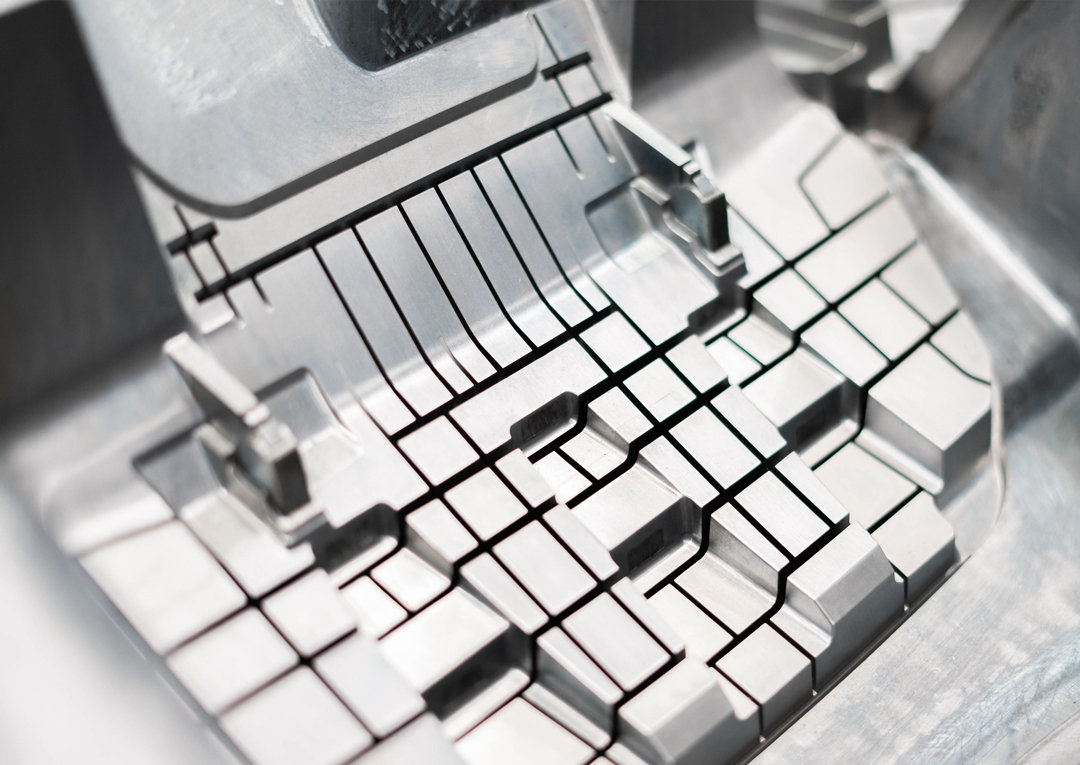

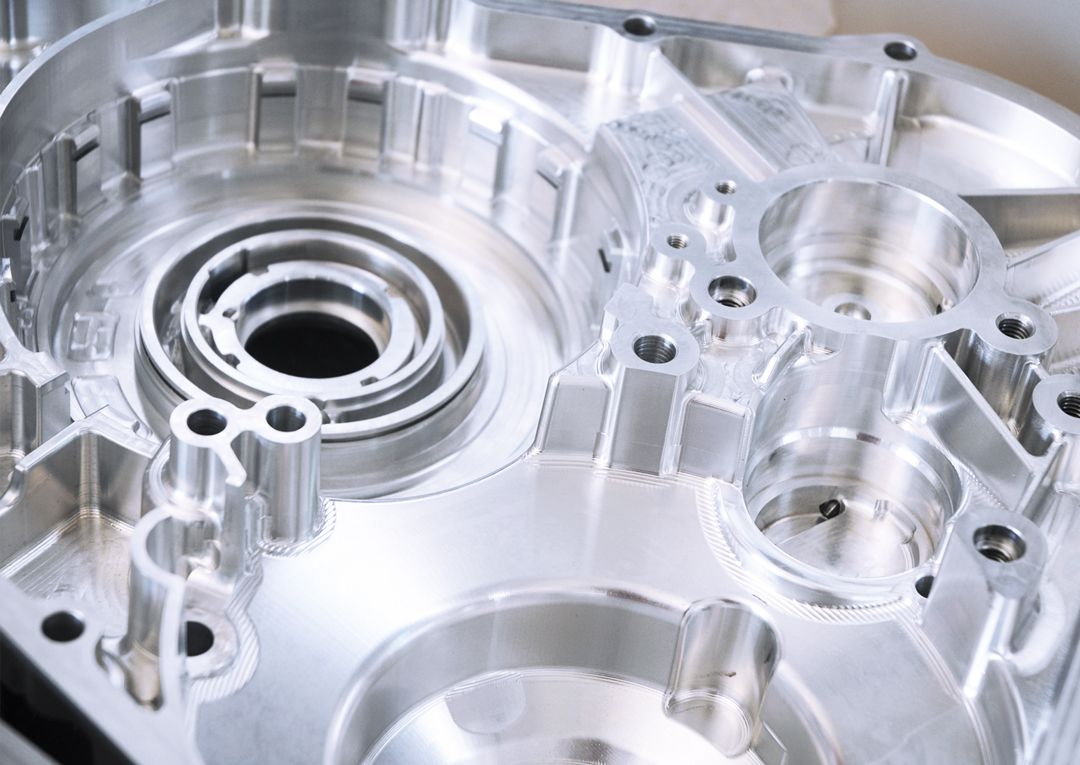

Checking Fixtures & High Speed Milling

With a qualified team, advanced technology and more than 25 years’ experience in the engineering and manufacture of checking fixtures, we serve precision-oriented industries. We prioritize investment in cutting-edge technology, such as high-speed milling, 5-axis CNC machines and automated manufacturing systems. This guarantees exact results, even for complex geometries, vital for demanding industries, for which precision and time to market are essential.

Injection Moulding & Assembly

With fully autonomous automated production lines, along with electric machines that run on solar energy, our Thermoplastic Injection Moulding Unit works 24 hours a day, seven days a week. This allows to produce high-precision parts and components with consistent quality, in a continuous workflow.

Industries we find solutions for

We provide advanced integrated services to industries shaping the future. Our commitment to excellence and ongoing investments in technology deliver innovative, tailored solutions for our clients.

Automotive

Medical

Aerospace

Food & Beverage

Electro – Electronics

Agriculture & Industry

What clients say about us

Our News and Insights