Case Study

Automatic Analyser

Flexible, modular, connected, intuitive, robust, and precise: SPICA was developed to encompass all these features. It’s fair to say that it’s an analyzer set to revolutionize the automatic and multiparametric analytical platforms of the wine sector.

Case Study

Automatic Analyser

Flexible, modular, connected, intuitive, robust, and precise: SPICA was developed to encompass all these features. It’s fair to say that it’s an analyzer set to revolutionize the automatic and multiparametric analytical platforms of the wine sector.

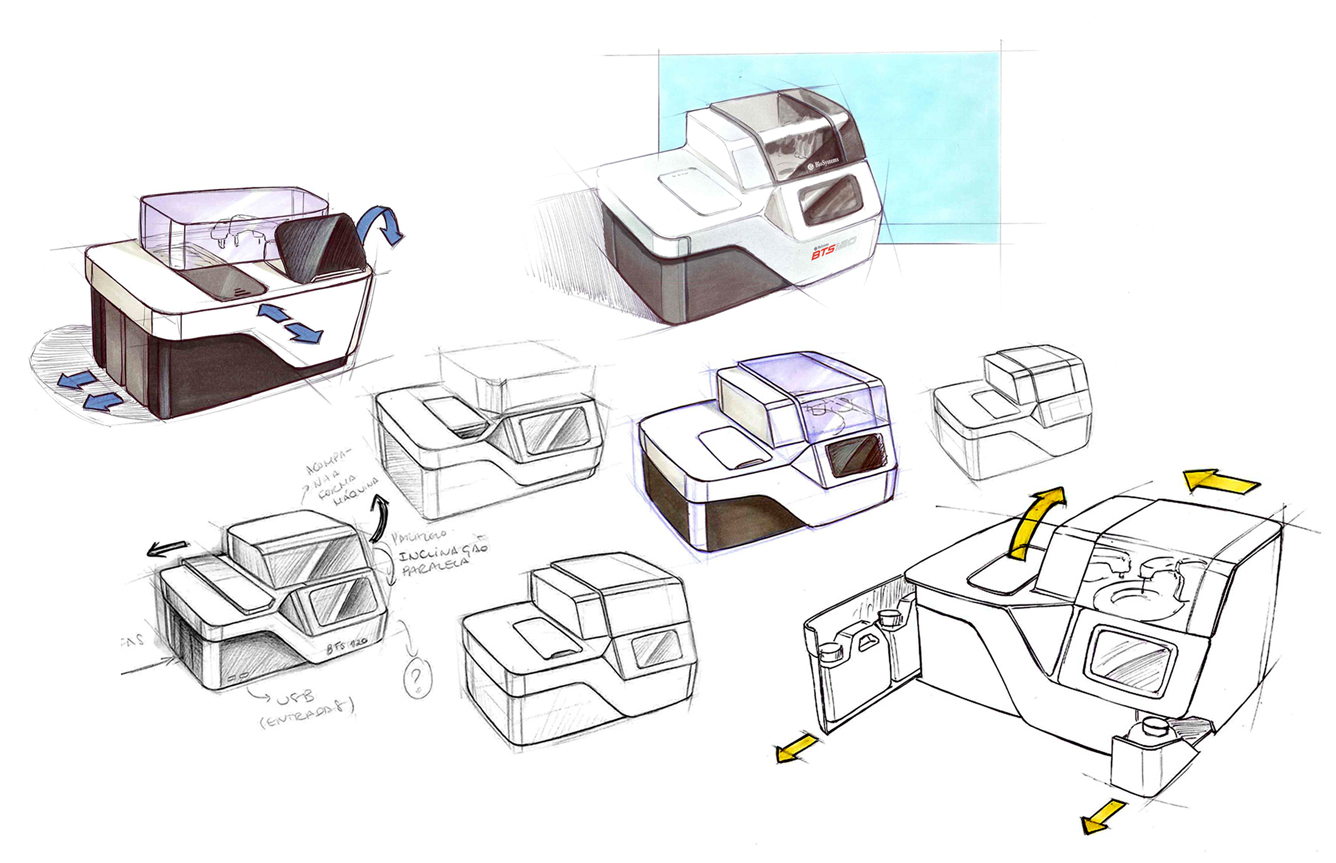

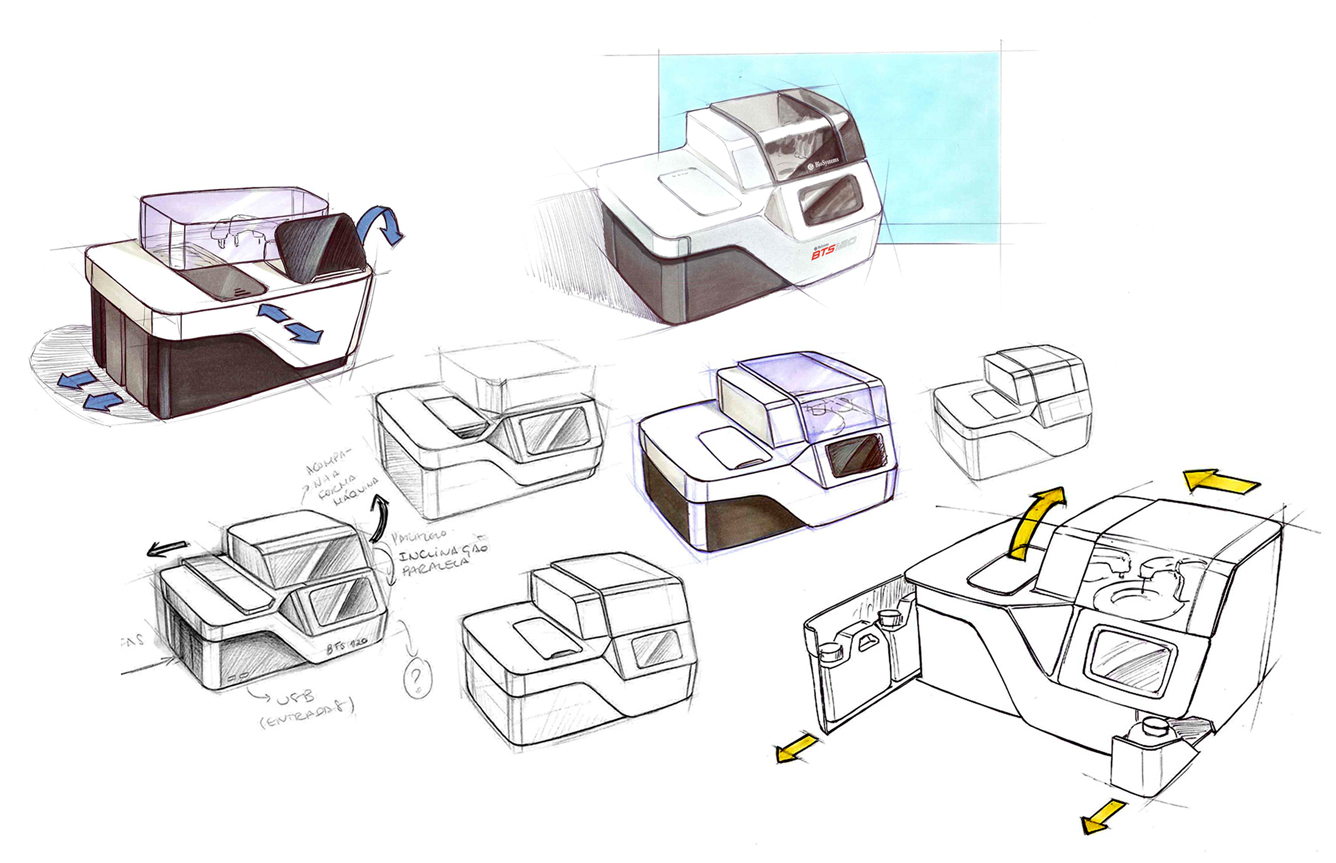

1. New Product Design

— New Product Design, Prototyping and Small Series Business Unit

In this project, the challenge lay in crafting a cost-effective design, despite the big dimensions and limited production volume. Our primary emphasis was on optimizing the structural framework and consumables. Furthermore, it was crucial for the design to reflect and enhance the Biosystems brand image.

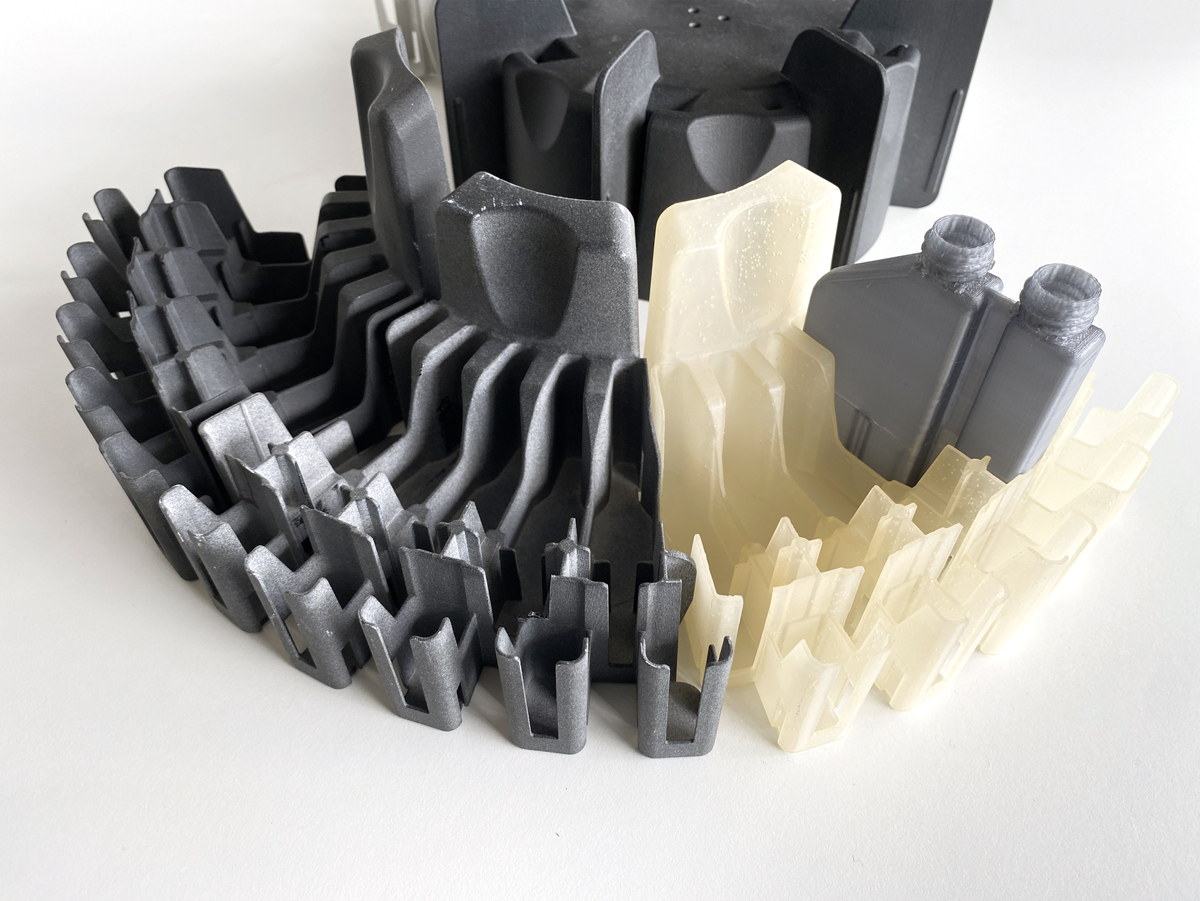

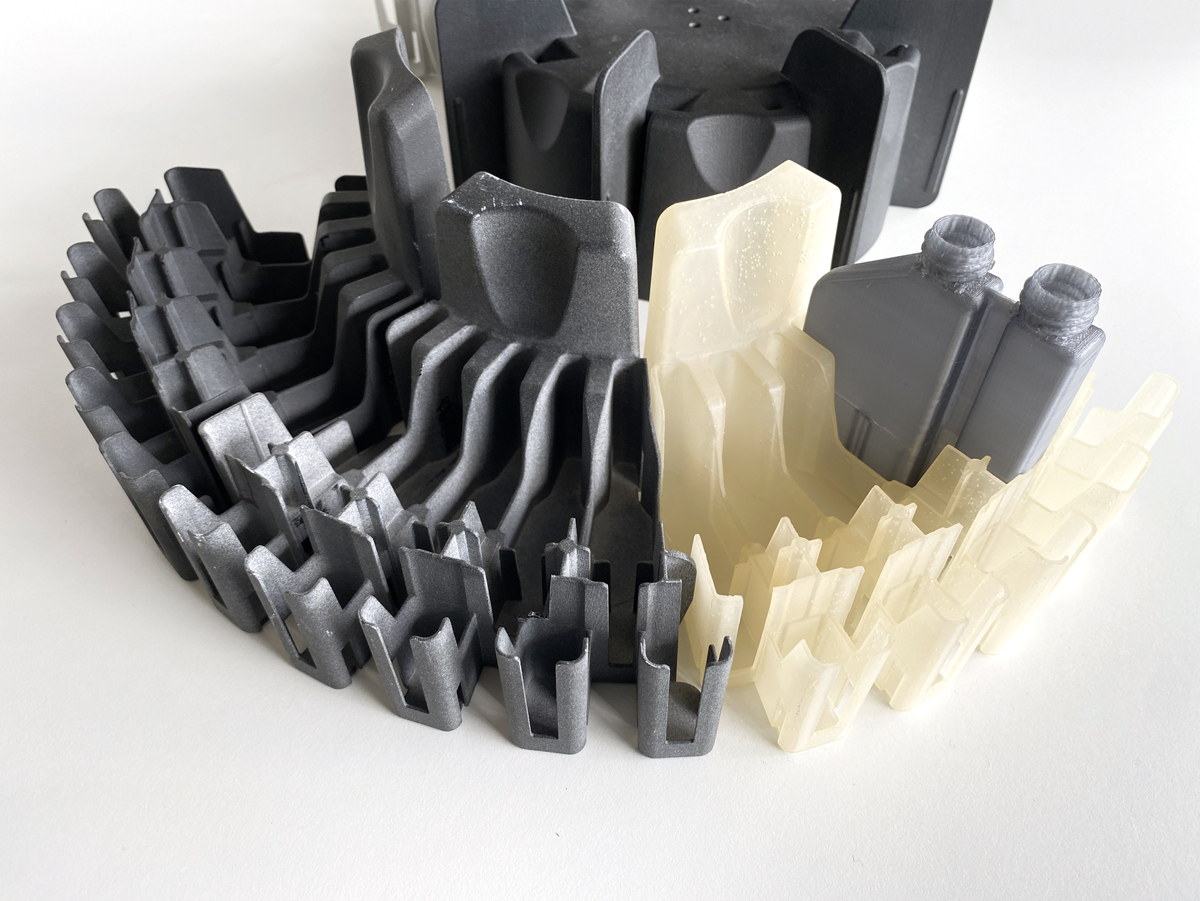

2. Prototyping

To ensure the highest quality and market success of the final product, we utilized a range of our cutting-edge technologies for effective component prototyping. The overall structure was prototyped in metal, while we employed 3D printing for crafting sample racks. Additionally, we developed prototypes for the reagent bottles.

2. Prototyping

To ensure the highest quality and market success of the final product, we utilized a range of our cutting-edge technologies for effective component prototyping. The overall structure was prototyped in metal, while we employed 3D printing for crafting sample racks. Additionally, we developed prototypes for the reagent bottles.

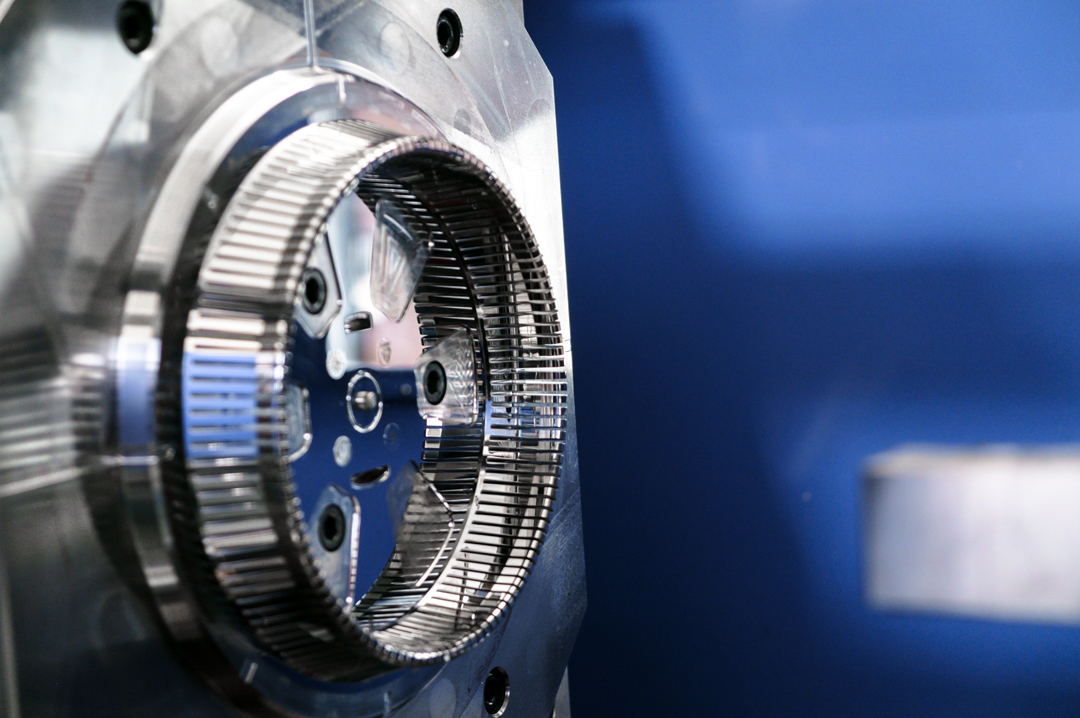

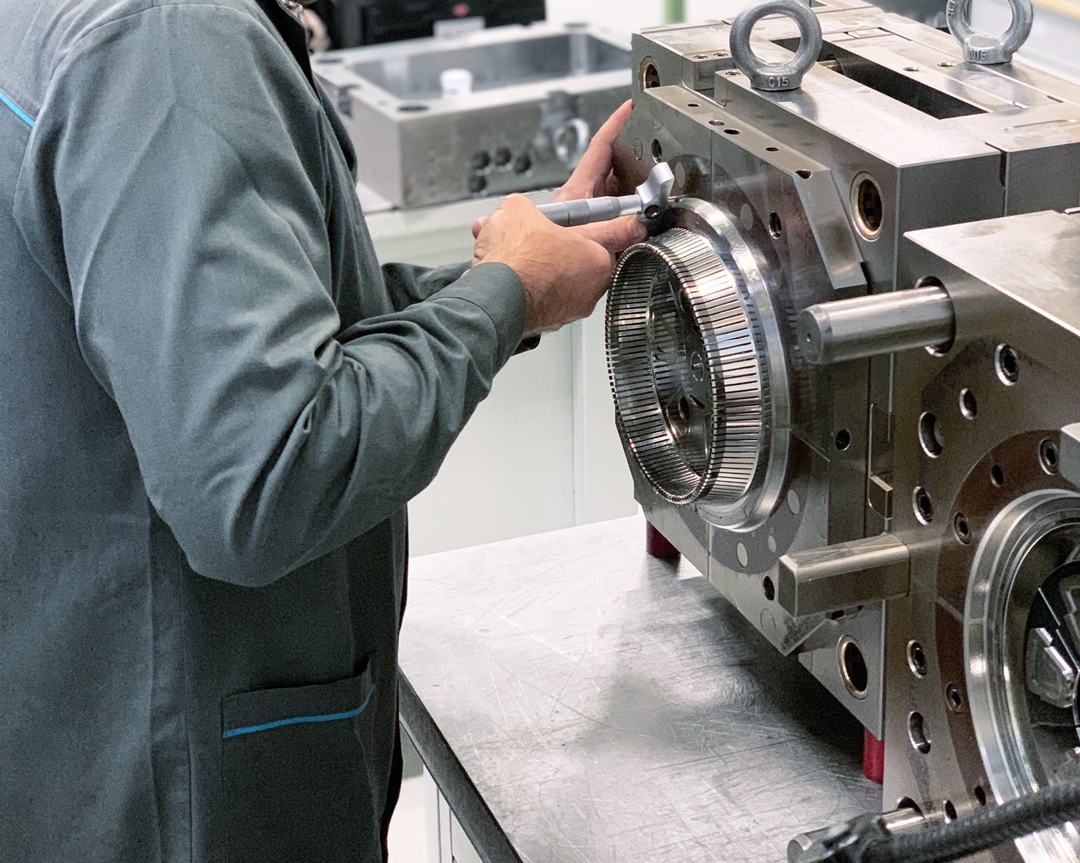

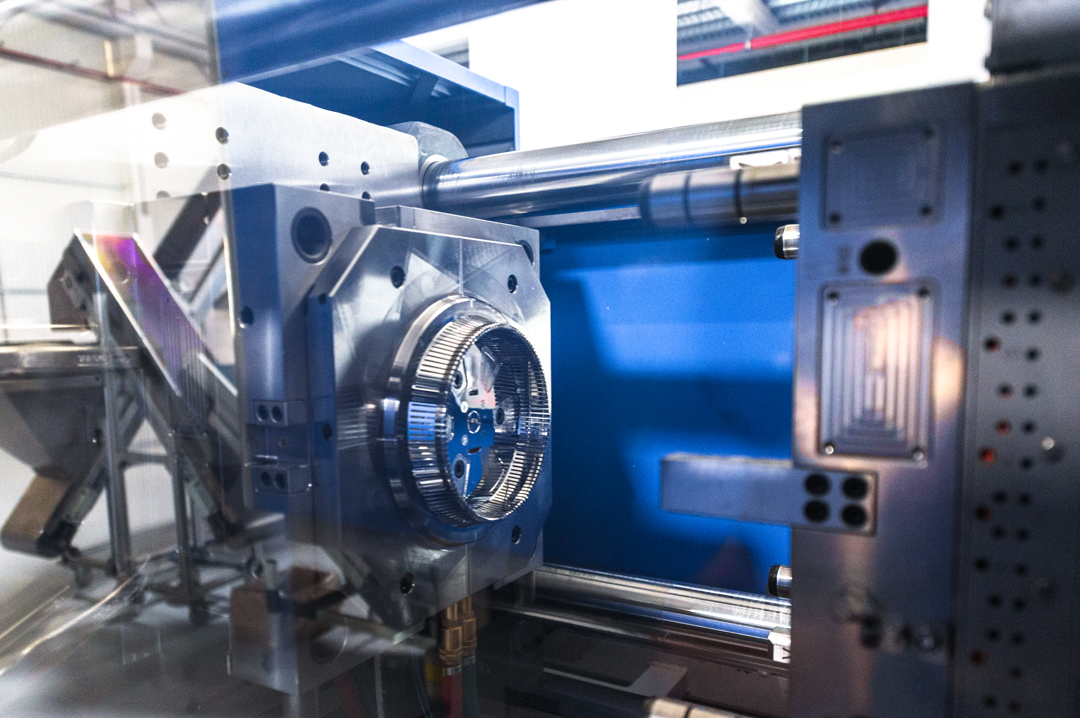

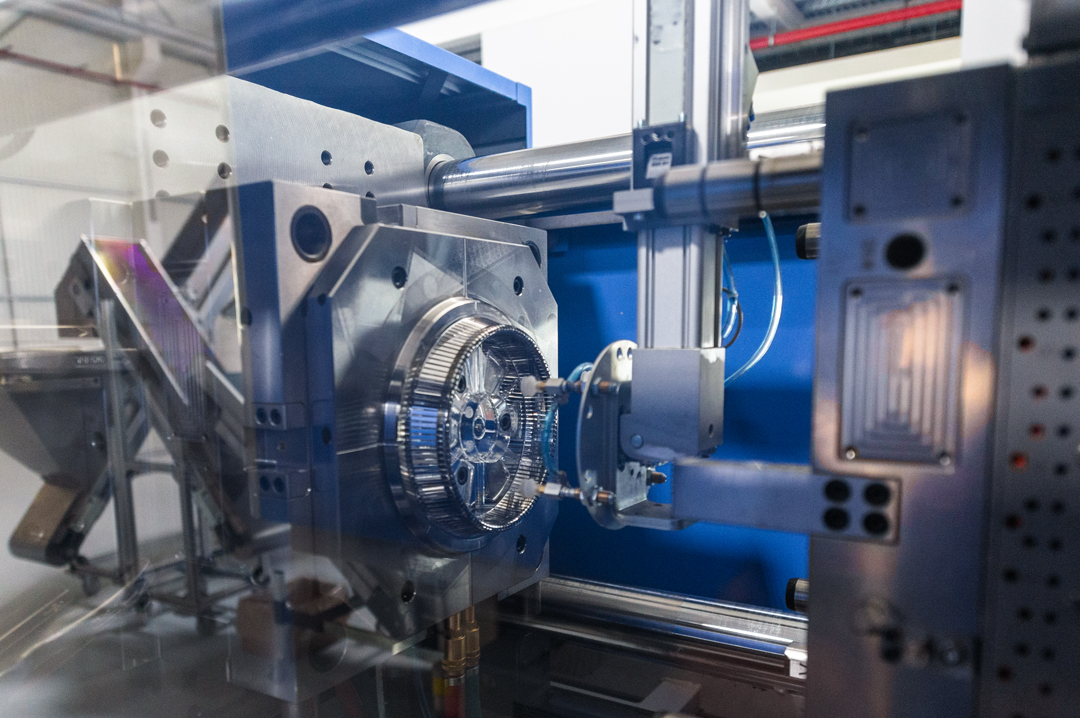

3. Mould Manufacturing

— Mould Making & Validation Business Unit

We developed moulds for three key components of SPICA: for the sample racks, for the analysis rotor, and also silicone moulds for the self-closing reagent caps.

4. Injection Moulding

— Injection Moulding & Assembly Business unit

The SPICA project integrated various solutions available in our industrial complex, which was also notable in the final phase of the product development cycle. In our specialized unit for high-precision components production, using thermoplastic injection, we inject the analysis rotor and the self-closing caps for the reagents.

Final Product

With dedicated teams for each phase of the project’s development, an integrated system, and cohesive processes, we can ensure time and cost efficiency and quality in all stages, involving the client from the beginning. In the end, the result is an innovative device that caters to various analytical needs and incorporates the latest mechanical assemblies, providing robustness, repeatability, and excellent precision.

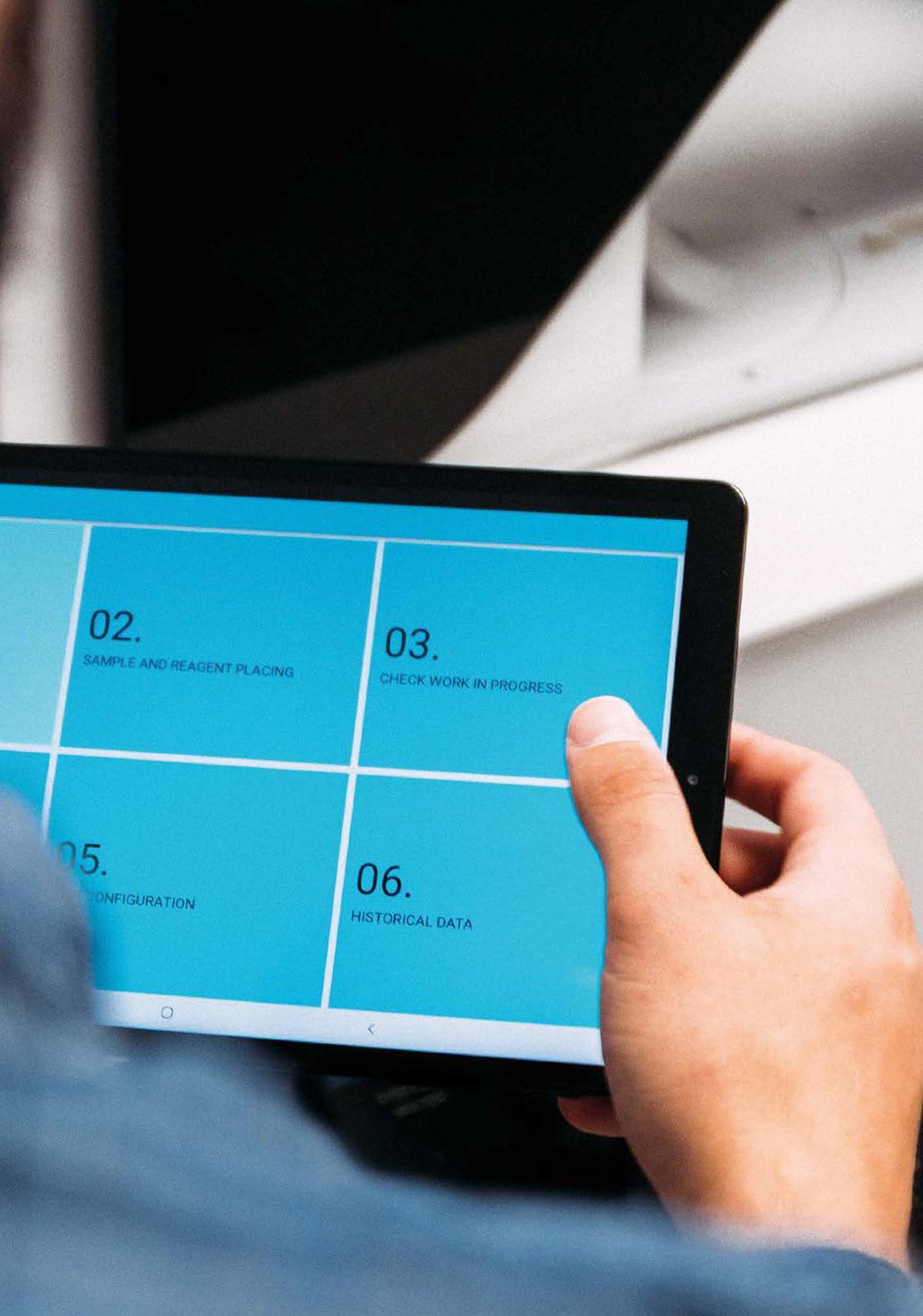

Spica APP – Image source: Biosystems

Samples Rotor – Image source: Biosystems

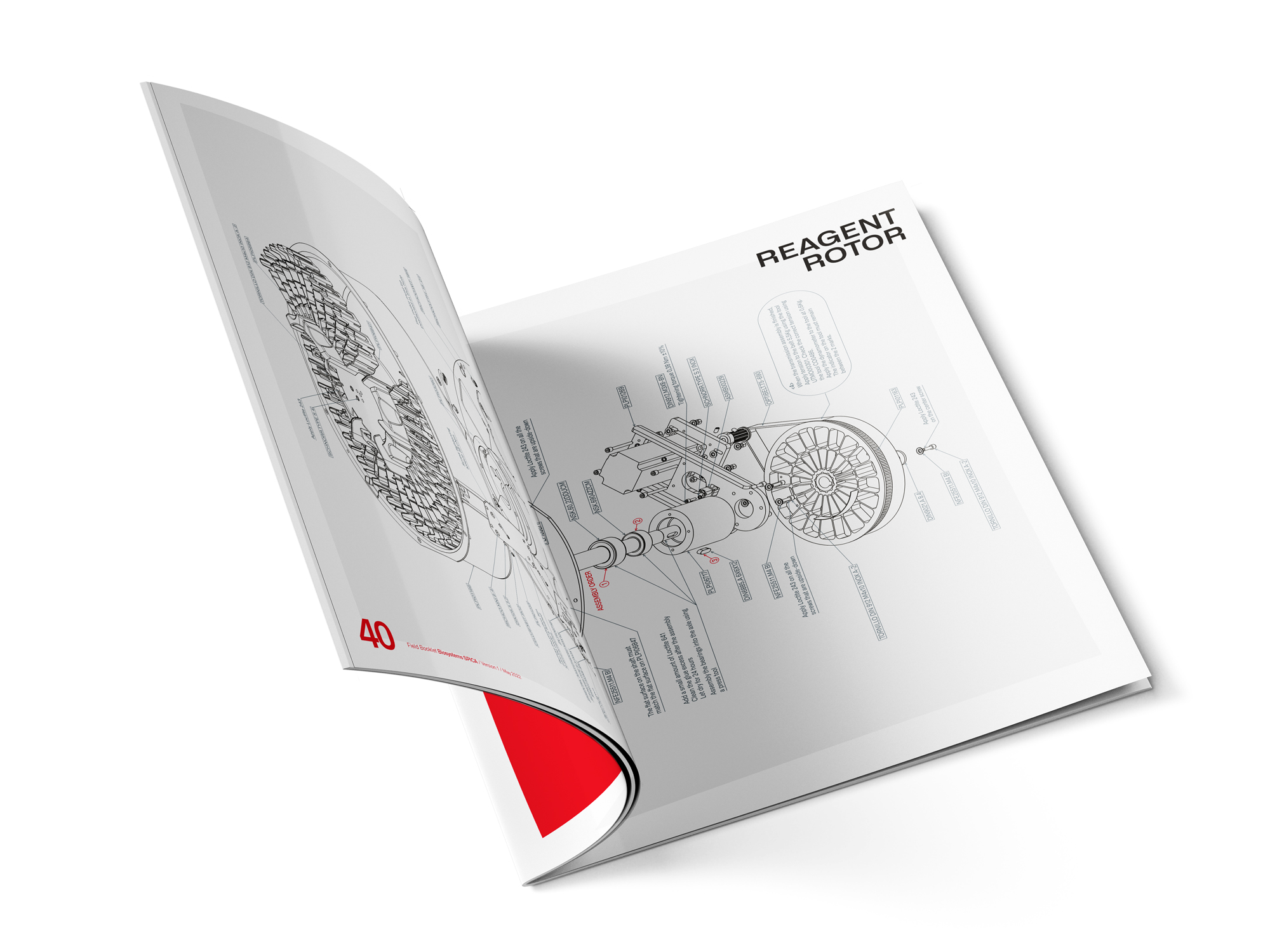

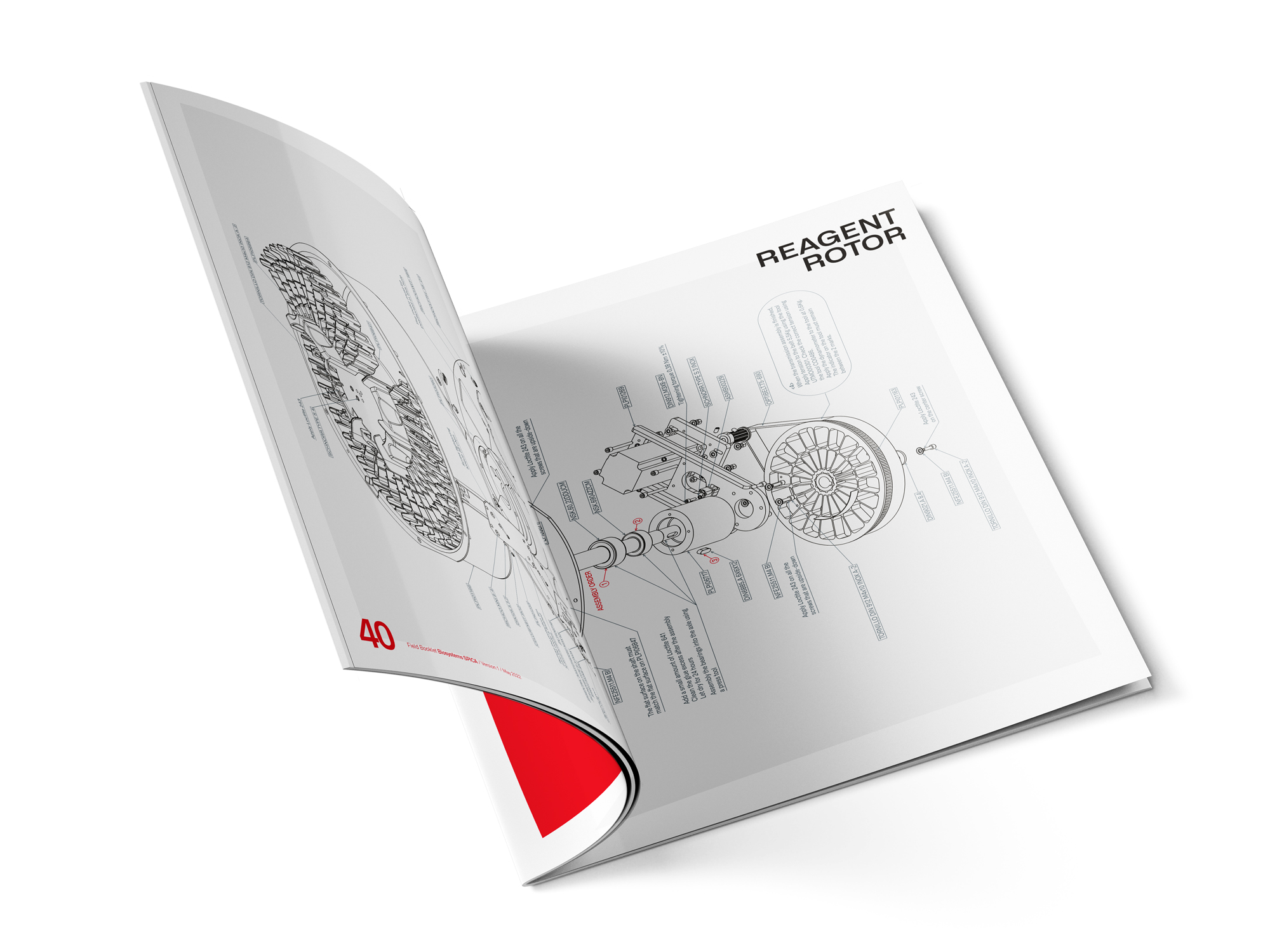

Reagent Rotor – Image source: Biosystems