Injection Moulding & Assembly

Our Injection Moulding Business Unit specializes in the production of high-precision thermoplastic components. For each of our products, a high degree of automation is established in the thermoplastic injection and assembly process, as well as artificial vision systems to guarantee 100% quality control, adding greater value to our clients. Thanks to high production efficiency and material optimization, injection moulding proves to be cost-effective, reducing overall manufacturing costs by integrating various features in a single injection and minimizing the need for costly and time-consuming assemblies.

Clean Room

ISO 7

The ISO 7 Clean Room provides air cleanliness levels of up to 10,000 particles (≥0.5µm) per cubic foot and a minimum of 60 air changes per hour. By upgrading our capabilities with an ISO 7 Clean Room, our aim is to serve the medical industry and the medical device manufacturing more regularly and prominently.

Reference Standards: ISO 9001, IATF 16949, ISO13485.

We are committed to maintaining strict quality control, complying with automotive and medical industry standards and ensuring the cleanliness and precision needed to produce high-quality molds and parts.

If you want to know more about our Policies, please consult us.

Injection Moulding Technologies

2K/3K Injection Moulding

Metal Insert Moulding

Reel-to-Reel Injection Moulding

Reverse Engineering

In-Moulding Assembly

“Variotherm” Injection Moulding

Back-Injection

Gas Assisted Injection Moulding

Our Facilities and Technologies

We work to ensure that our clients, in industries that are constantly evolving, remain competitive. Our investment in state-of-the-art technology contributes to this, as it allows precise control of the injection moulding process, streamlines production for quicker turnarounds and opens doors to new design possibilities, materials and techniques, fostering innovation.

Metrology & Quality Control Equipments

We apply high-precision measuring methods, ensuring that each part is within the required dimensional and positioning tolerances.

CMM Technologies

This technology ensures precise measurement, validation of mould dimensions and geometric characteristics, improving part quality and consistency, reducing defects, and saving time and costs in mold-making.

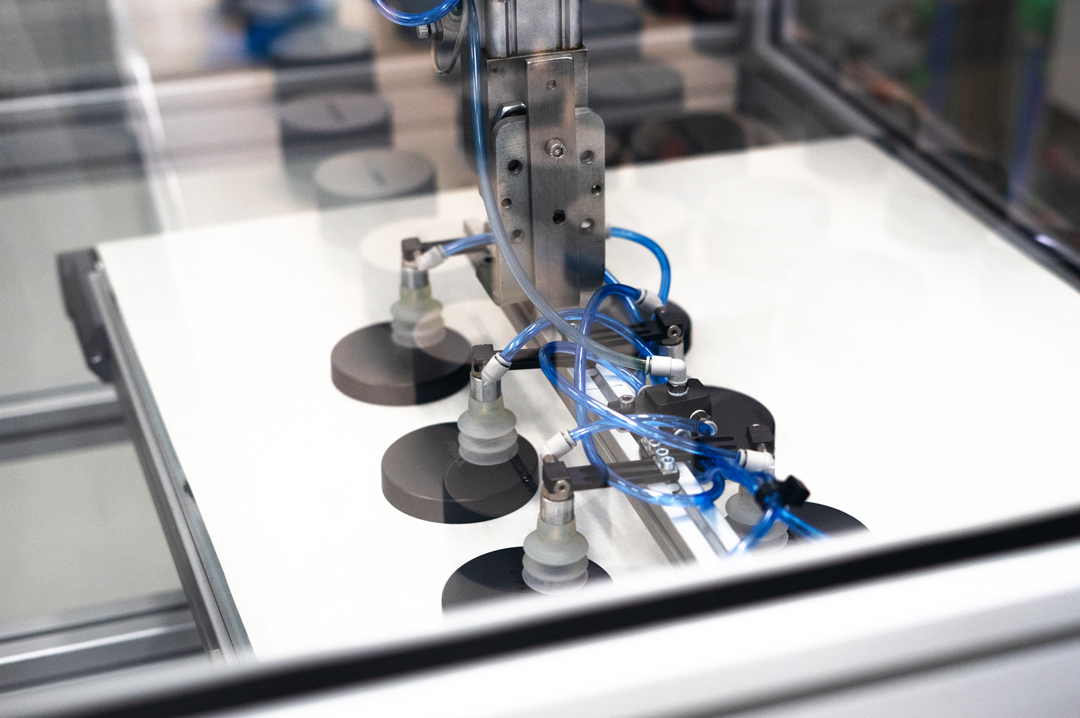

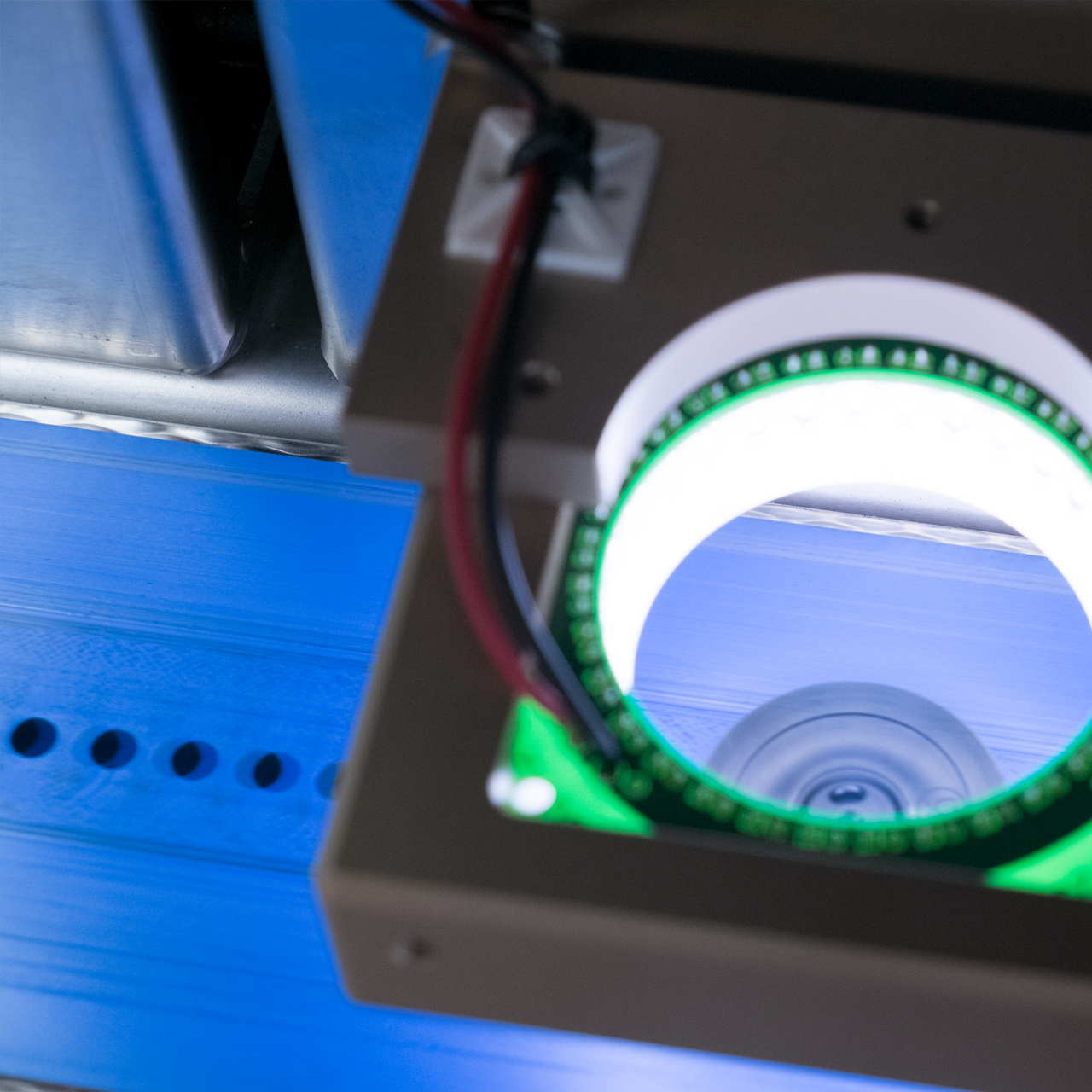

Control by Vision

This technology provides real-time monitoring and immediate feedback during the process, enabling rapid identification and correction of defects or inconsistencies, leading to improved quality control and potentially reducing the need for costly rework.

Automatic Visual Control

This advanced technology consistently and autonomously inspects and detects any flaws or irregularities in the parts, thereby enabling us to achieve strict quality control, uniformity and cost efficiency.