Mould Making & Validation

With more than 36 years of experience creating design, engineering and mould production solutions, we’ve gained strong expertise. We mix this know-how with advanced technologies, made even more effective by our speciaized teams in our dedicated factories. In our in-house Mould Trial and Validation Centre we ensure moulds work reliably in real production settings. This is vital for a stable, consistent process and mould qualification.

Ultra Precision Moulds

Up to 5 Ton

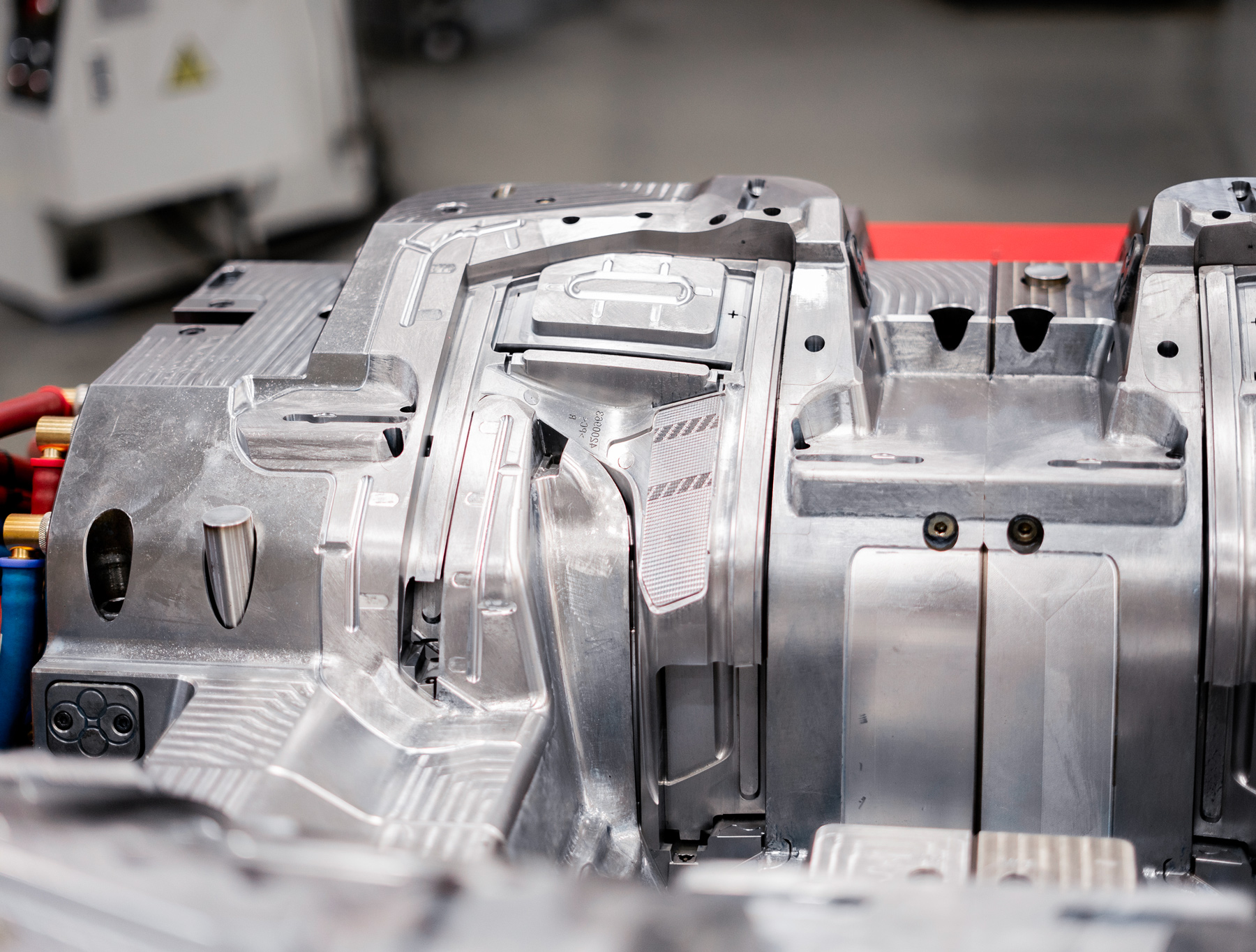

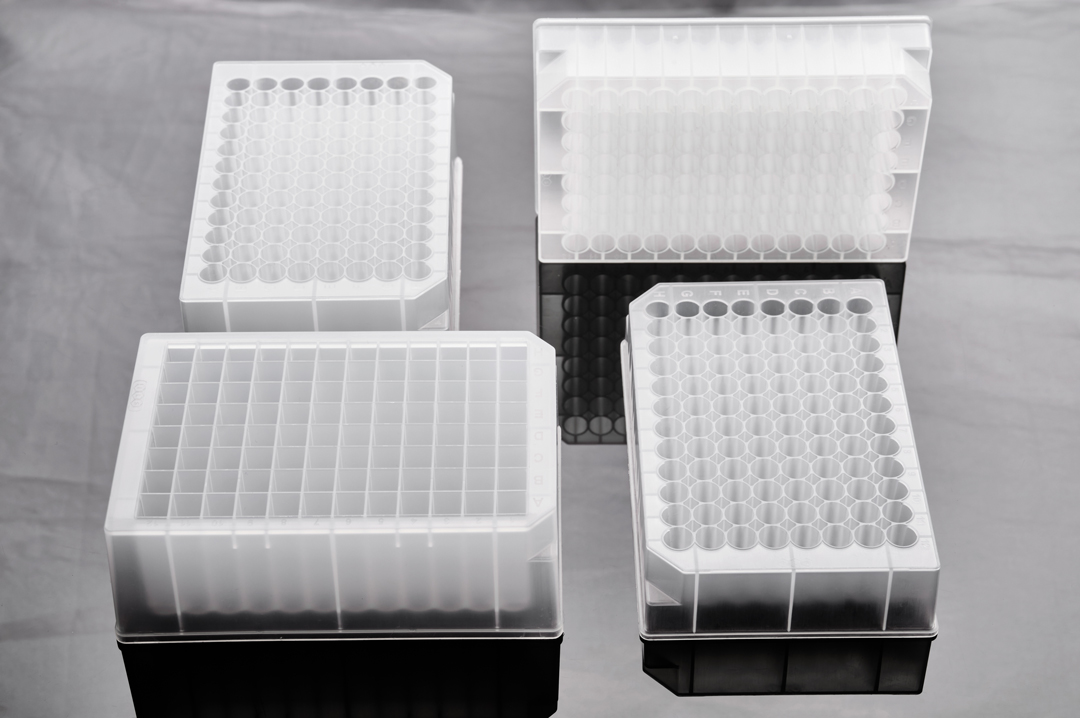

Operating under environmentally controlled conditions, we have technologies to machining moulds as precise as micro moulds and impression inserts for the medical and pharmaceutical sectors, microfluidic inserts with the tightest tolerances (+/-0.001mm) and steel optics for the automotive industry. In our Small Moulds Factory, flexible robotic machining cells also contribute to assuring consistently top quality.

Large Moulds

& Precision Milling

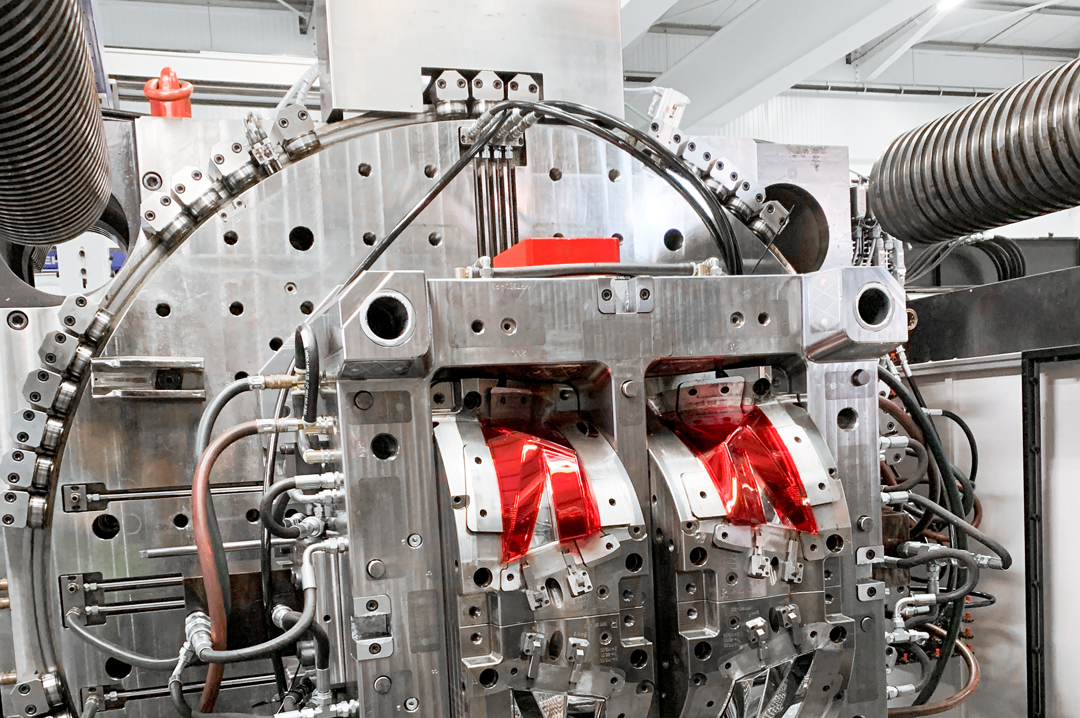

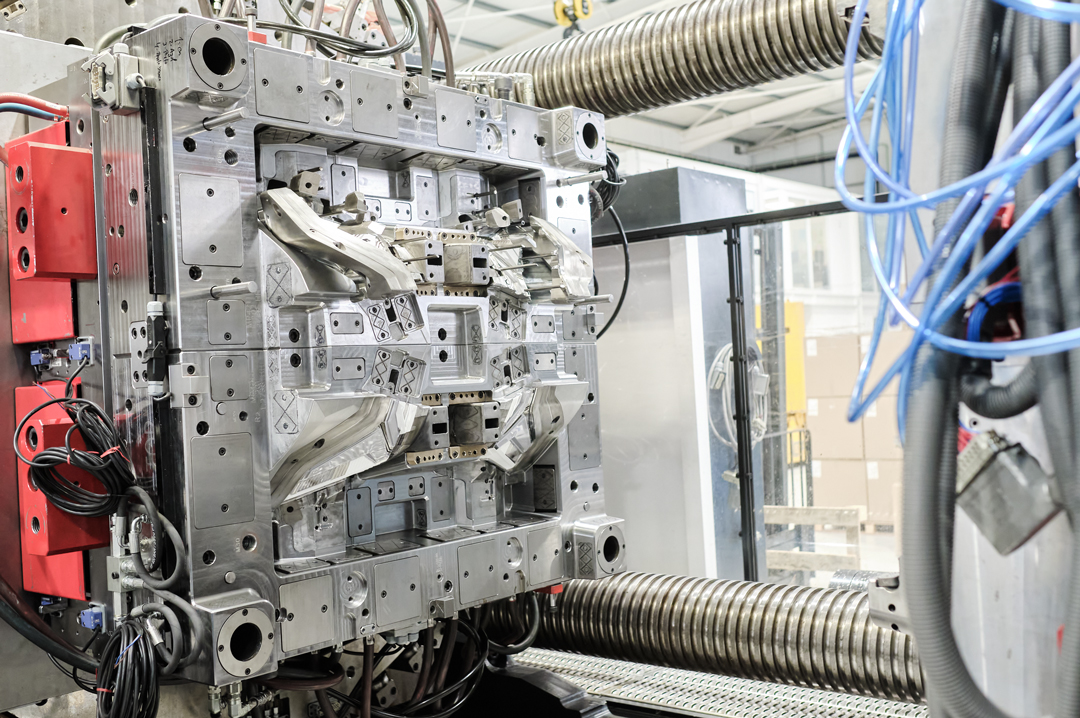

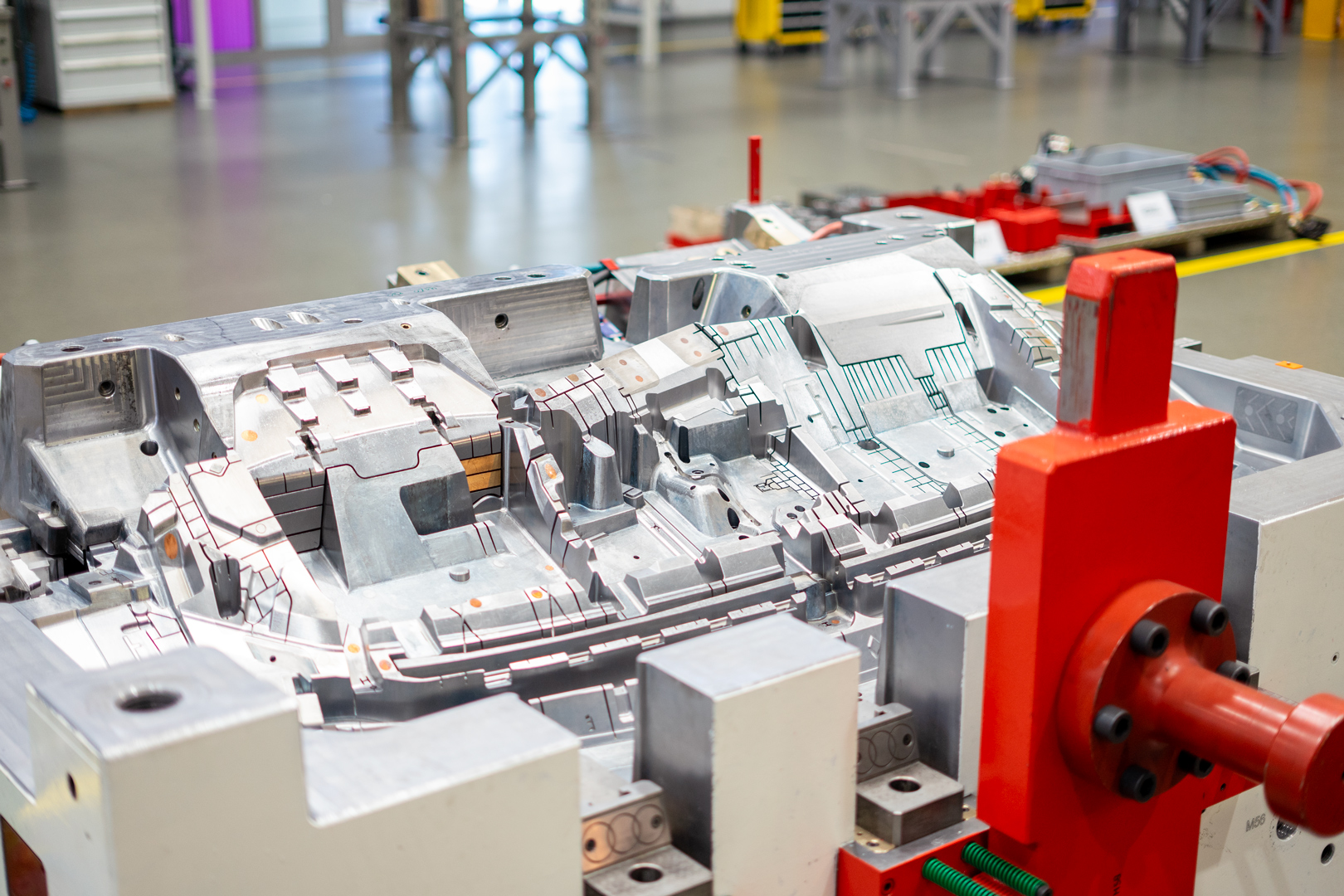

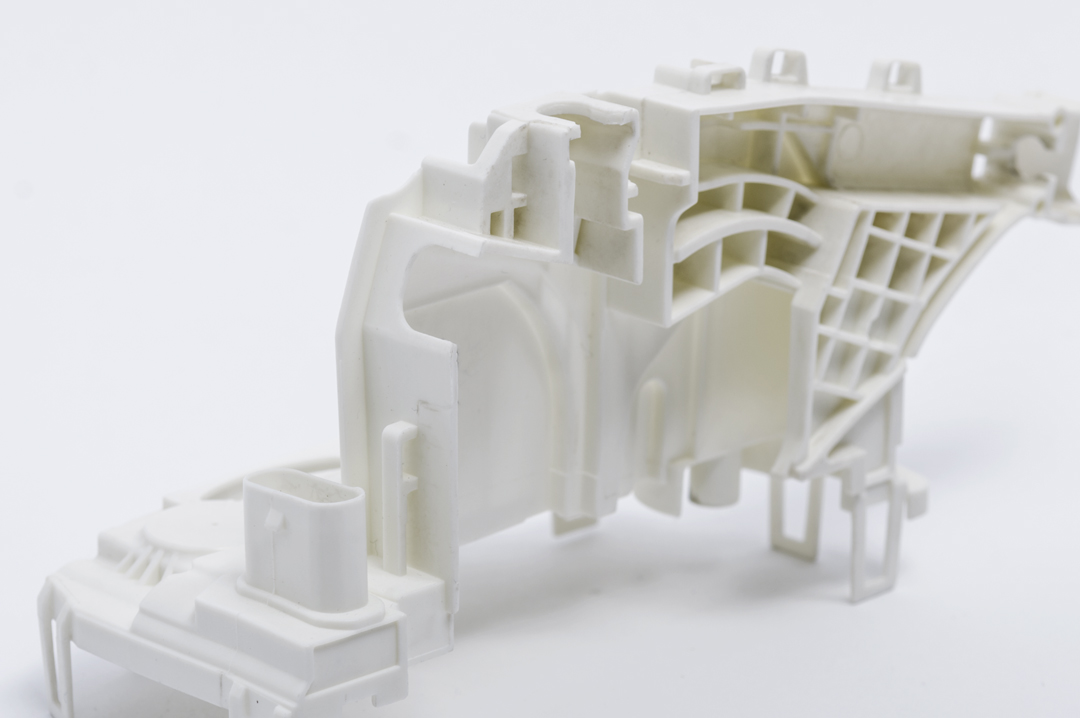

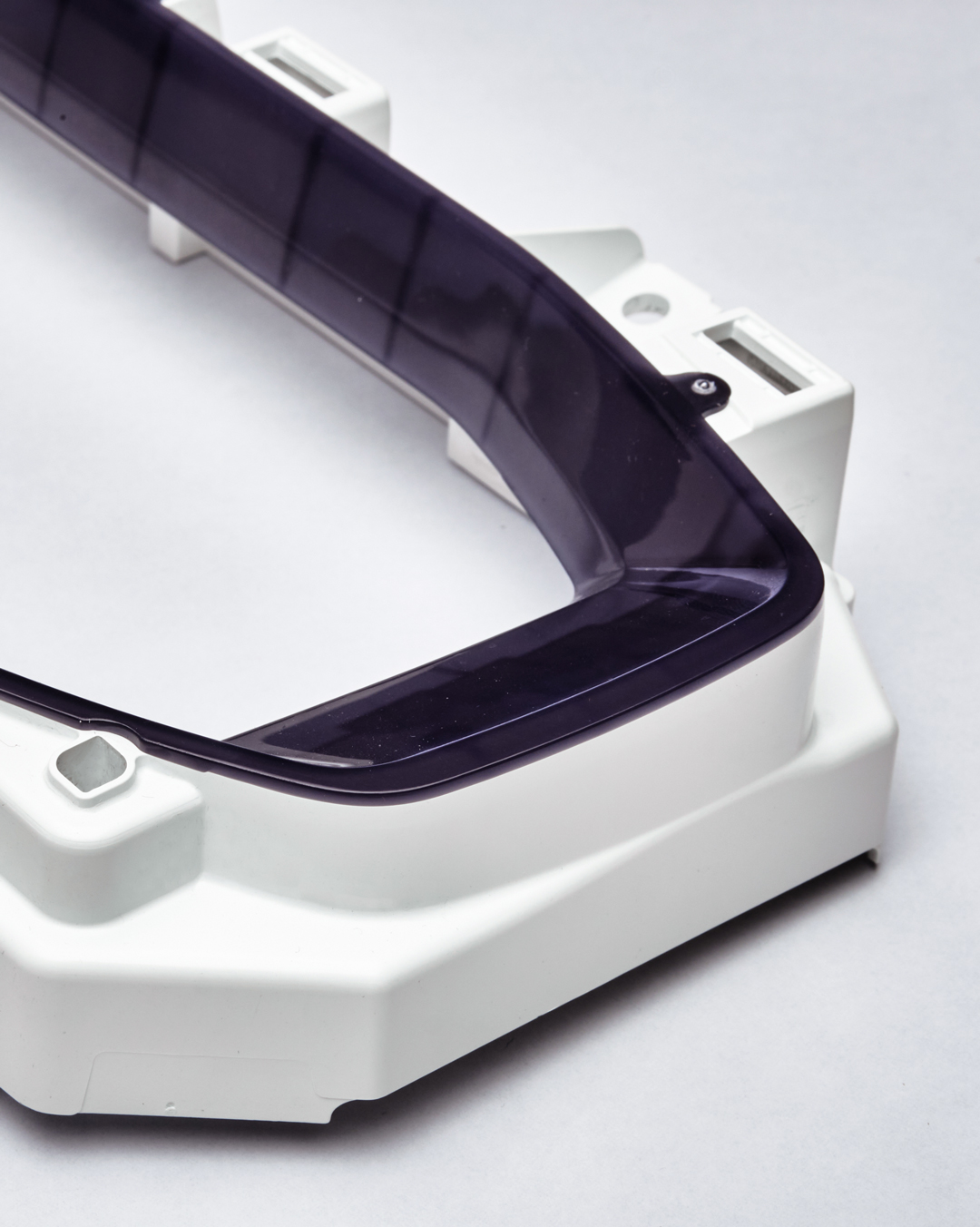

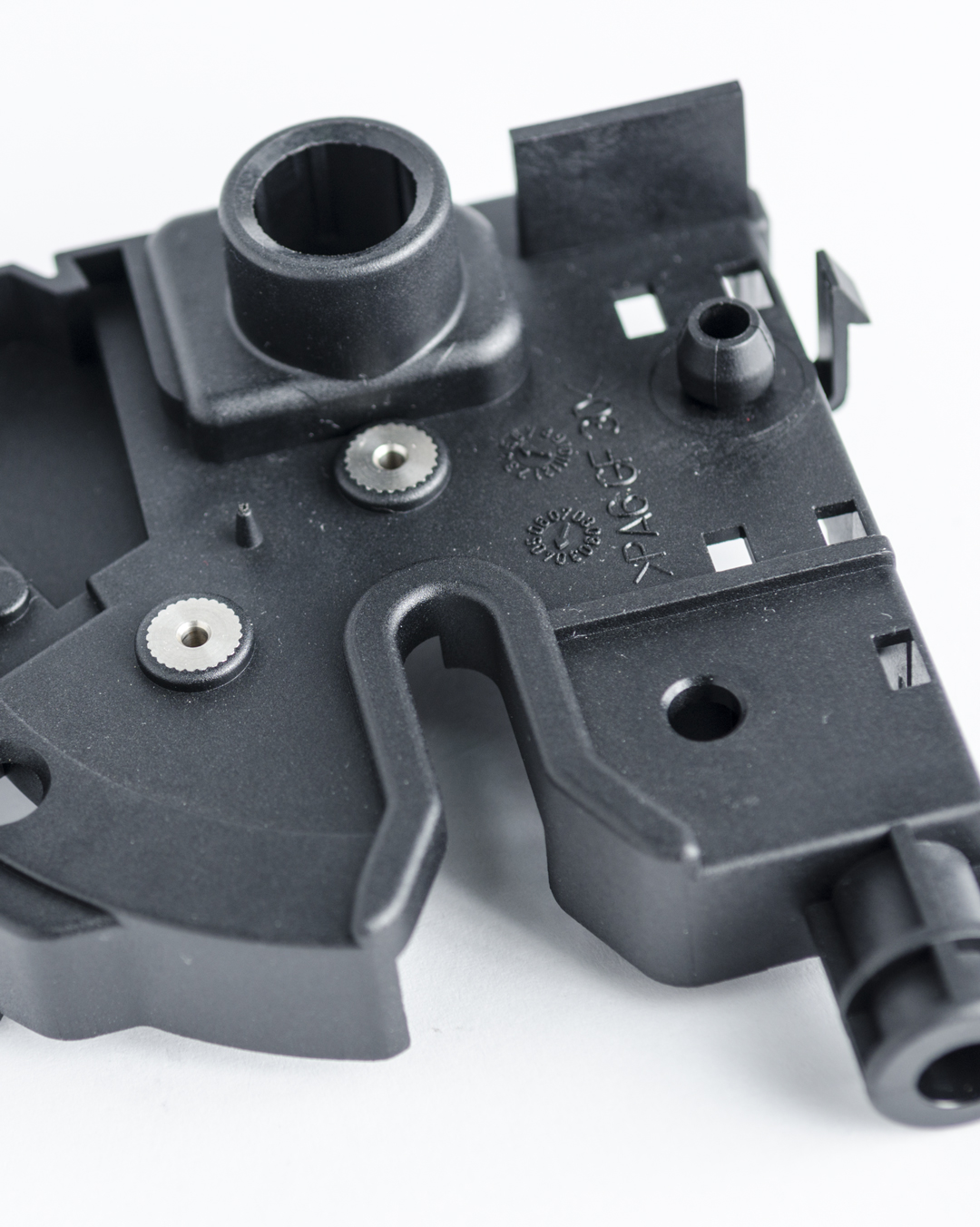

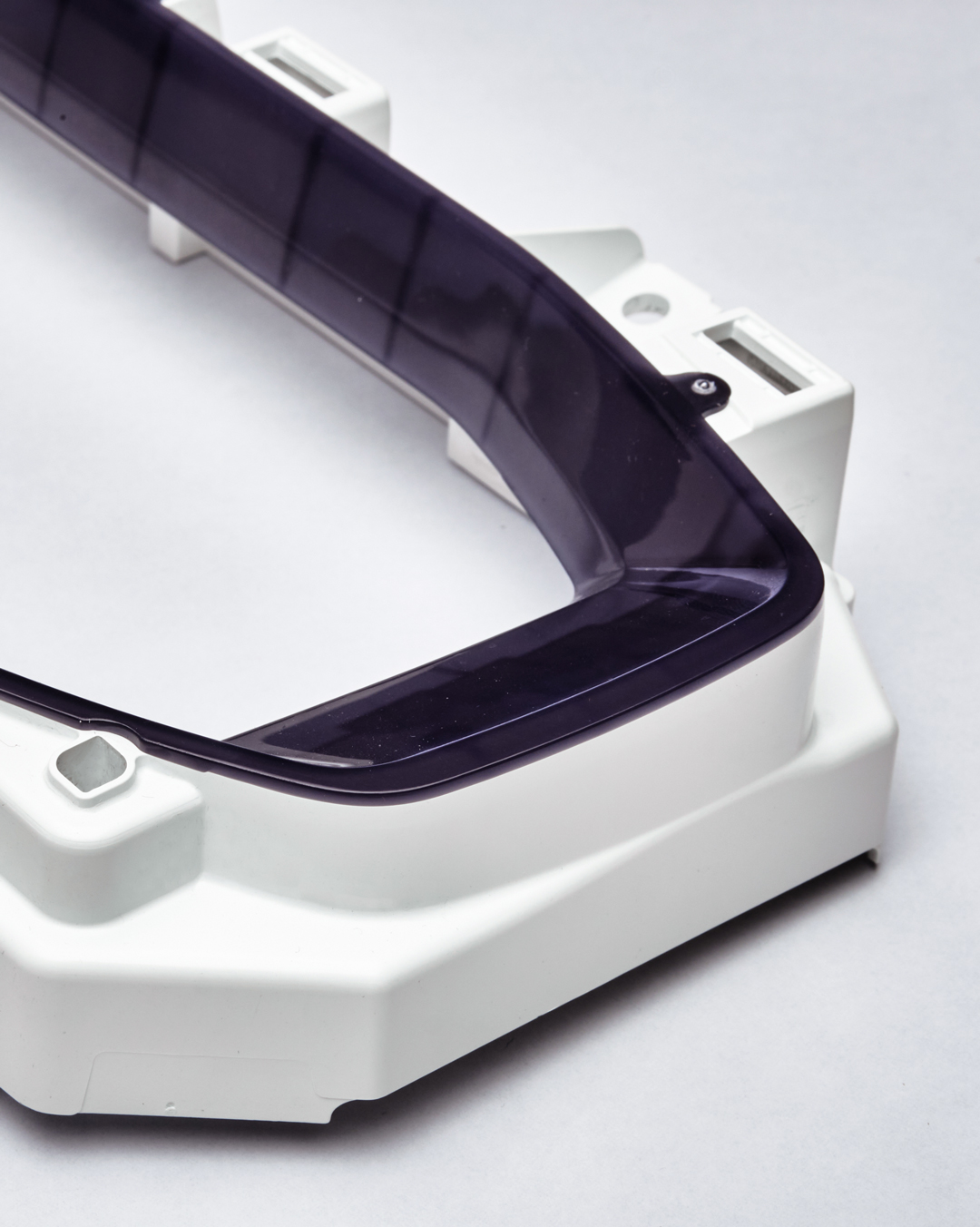

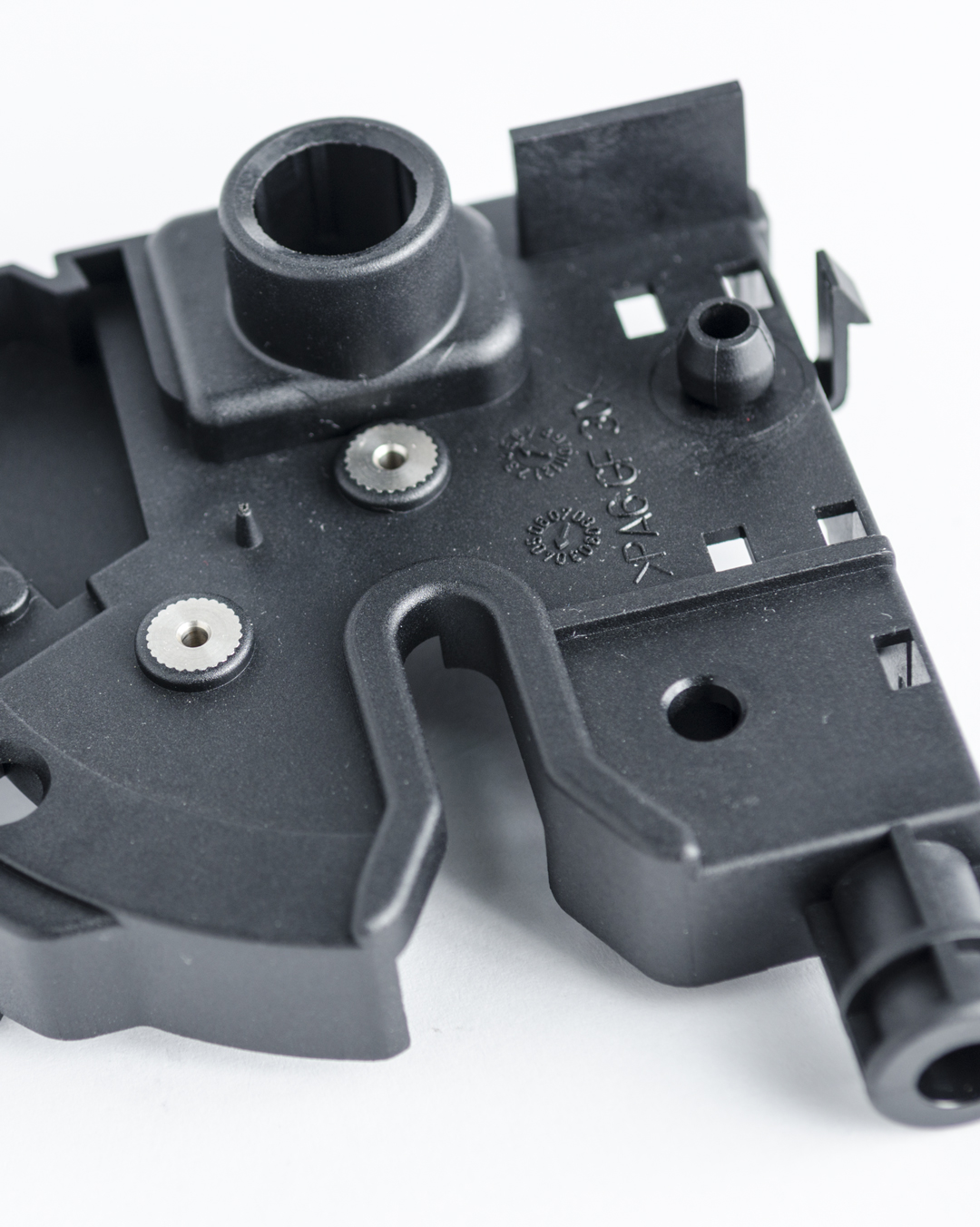

In the Large Moulds Factory, we manufacture various types of moulds to meet specific needs, including core-back, index plate, sandwich moulds, as well as moulds for two or three component parts. These moulds employ rotary and/or transfer technology, catering to the production requirements of large interior parts, spoilers, vehicle lighting, and large plastic air intake parts.

Mould Manufacturing Process

1 – Quotation

2 – Design & Engineering

3 – Prototype Tooling

4 – Serial Tool Production

5 – Moulds Validation

Dedicated Facilities & Technologies

Specialized facilities with dedicated technologies and resources allows us to develop focused expertise and optimized processes. This specialization enhances efficiency, quality, and the ability to meet specific client needs, resulting in more effective and tailored solutions.

Industries we work for

We provide solutions tailored to the specific demands and stringent standards of global industries. With over three decades of experience, we have cultivated the flexibility and expertise necessary to deliver high-quality moulds that precisely match the distinctive requirements of each sector.

Automotive

Medical

Electro-Electronics

Food & Beverage

Houseware

Agriculture & Industry

Packaging

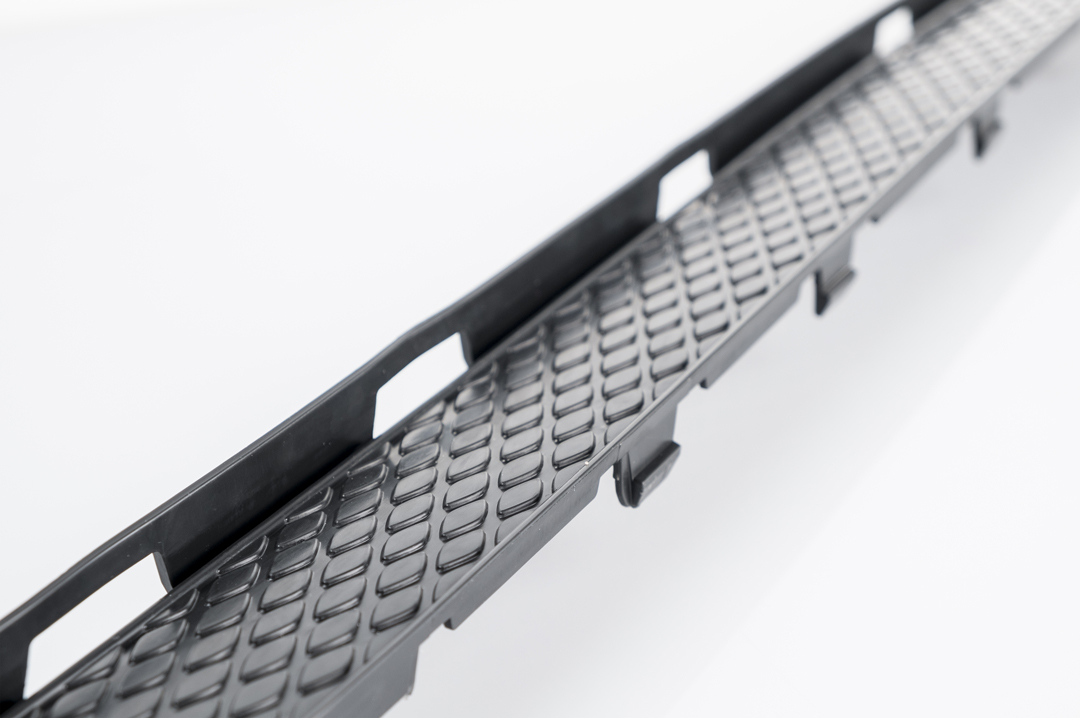

automotive exterior

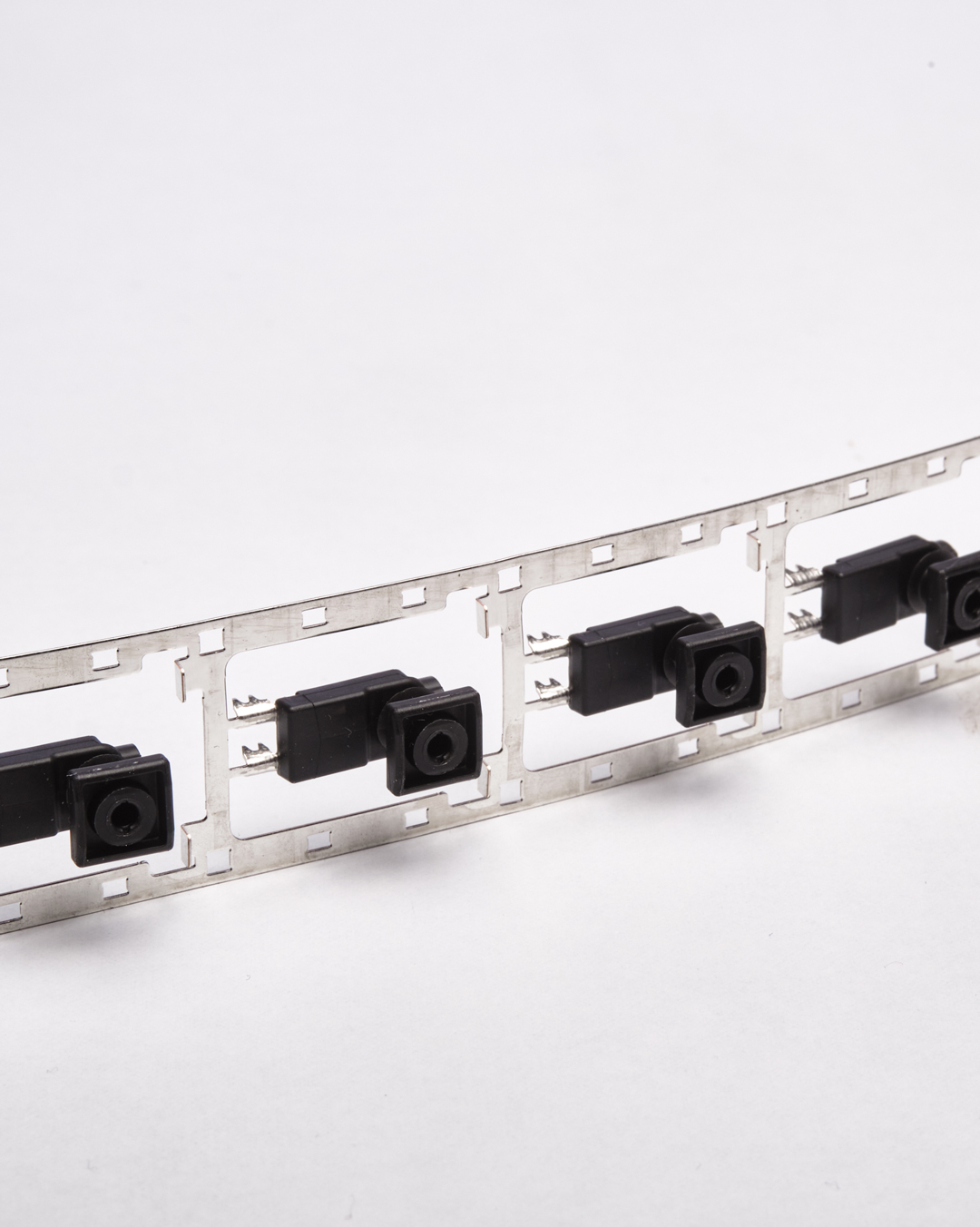

electro-electronics

medical

electro-electronics

packaging

automotive interiors

automotive grid

automotive doors

Injection Moulds Technologies

Advanced technologies enable enhanced precision, efficiency, and versatility in manufacturing. These technologies allow for tighter tolerances, faster production cycles, and the ability to work with a wider range of materials, ultimately leading to higher-quality products and reduced costs.

2K/3K Injection Moulding

Metal Insert Moulding

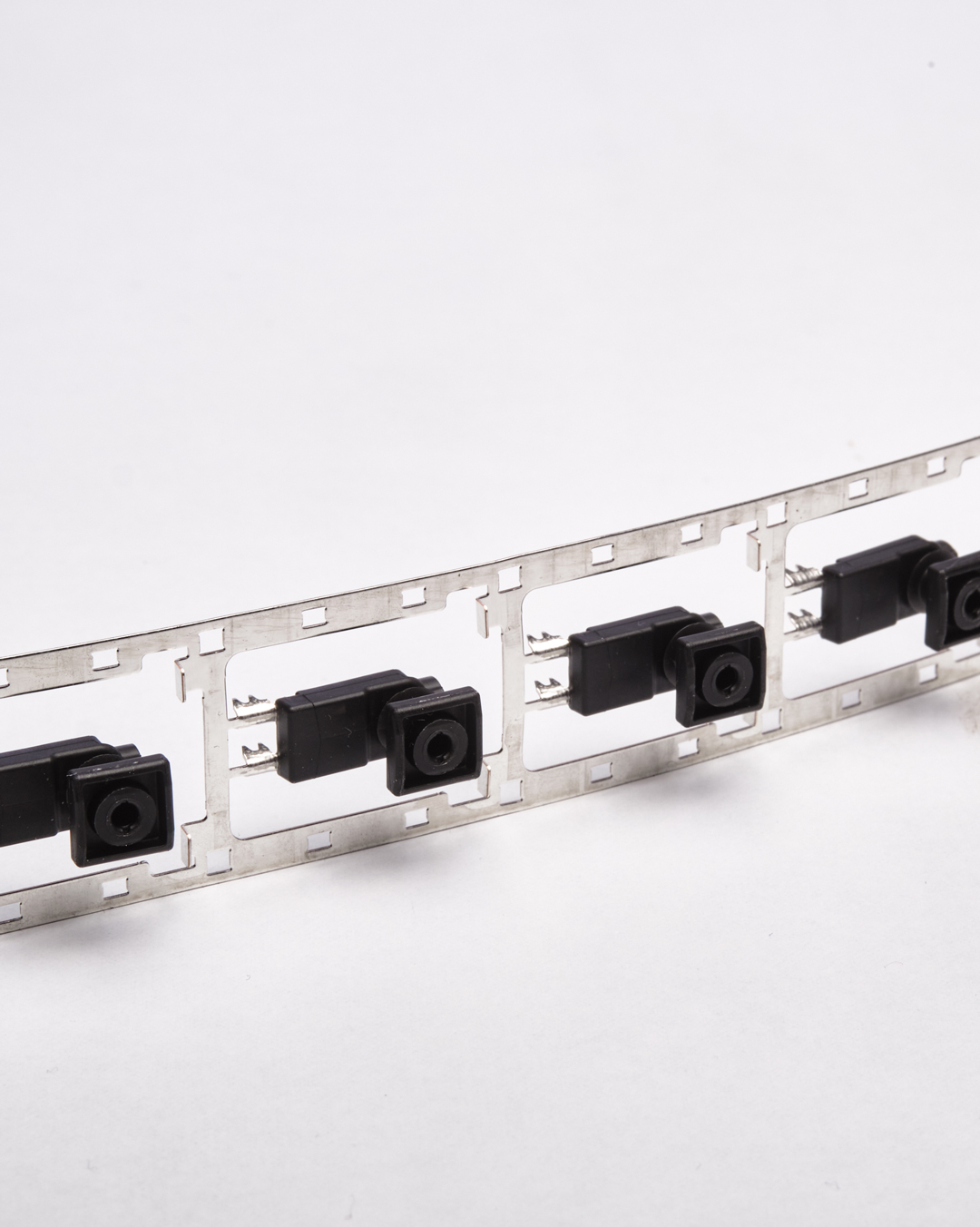

Reel-to-Reel Injection Moulding

In-Moulding Assembly

“Variotherm” Injection Moulding

Back-Injection

Gas Assisted Injection Moulding

Injection Moulds Technologies

Advanced technologies enable enhanced precision, efficiency, and versatility in manufacturing. These technologies allow for tighter tolerances, faster production cycles, and the ability to work with a wider range of materials, ultimately leading to higher-quality products and reduced costs.

2K/3K Injection Moulding

Metal Insert Moulding

Reel-to-Reel Injection Moulding

In-Moulding Assembly

“Variotherm” Injection Moulding

Back-Injection

Gas Assisted Injection Moulding

Try-Out & Validation Center

Our Mould Trial and Validation Centre has been set up to test a wide range of moulds and injection technologies, such as 2K and 3K injection, gas-assisted injection, and metal insertion over moulding.

We have built quality into the DNA of our moulds, combining the experience of our engineers with state-of-the-art equipment, ranging from 55T to 2300T.

All the conditions are in place to test and validate our clients’ moulds in a production environment. This is crucial, as achieving a stable and repeatable process is part of a mould’s qualification. We offer engineering solutions, with flexible and optimized processes.